Details

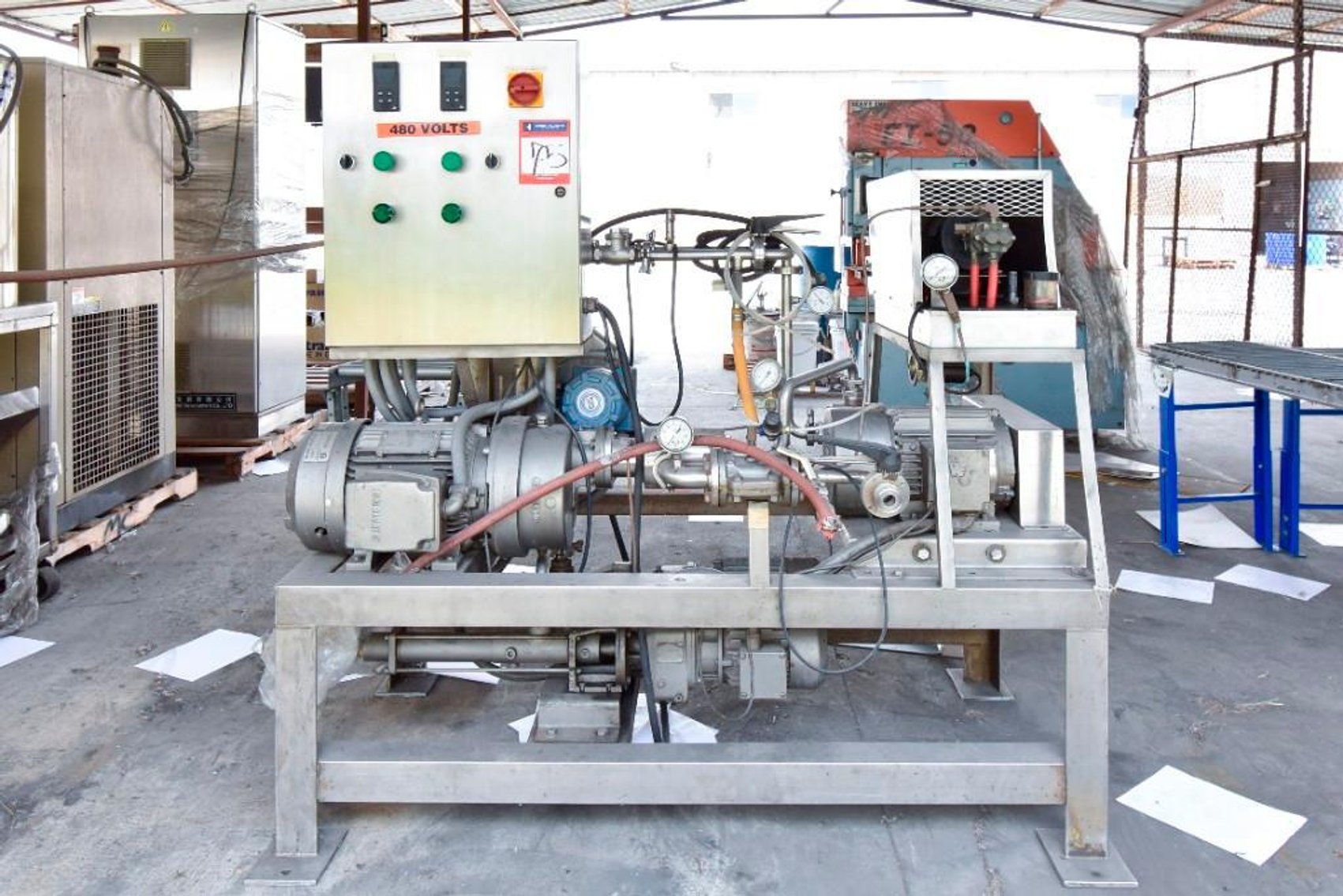

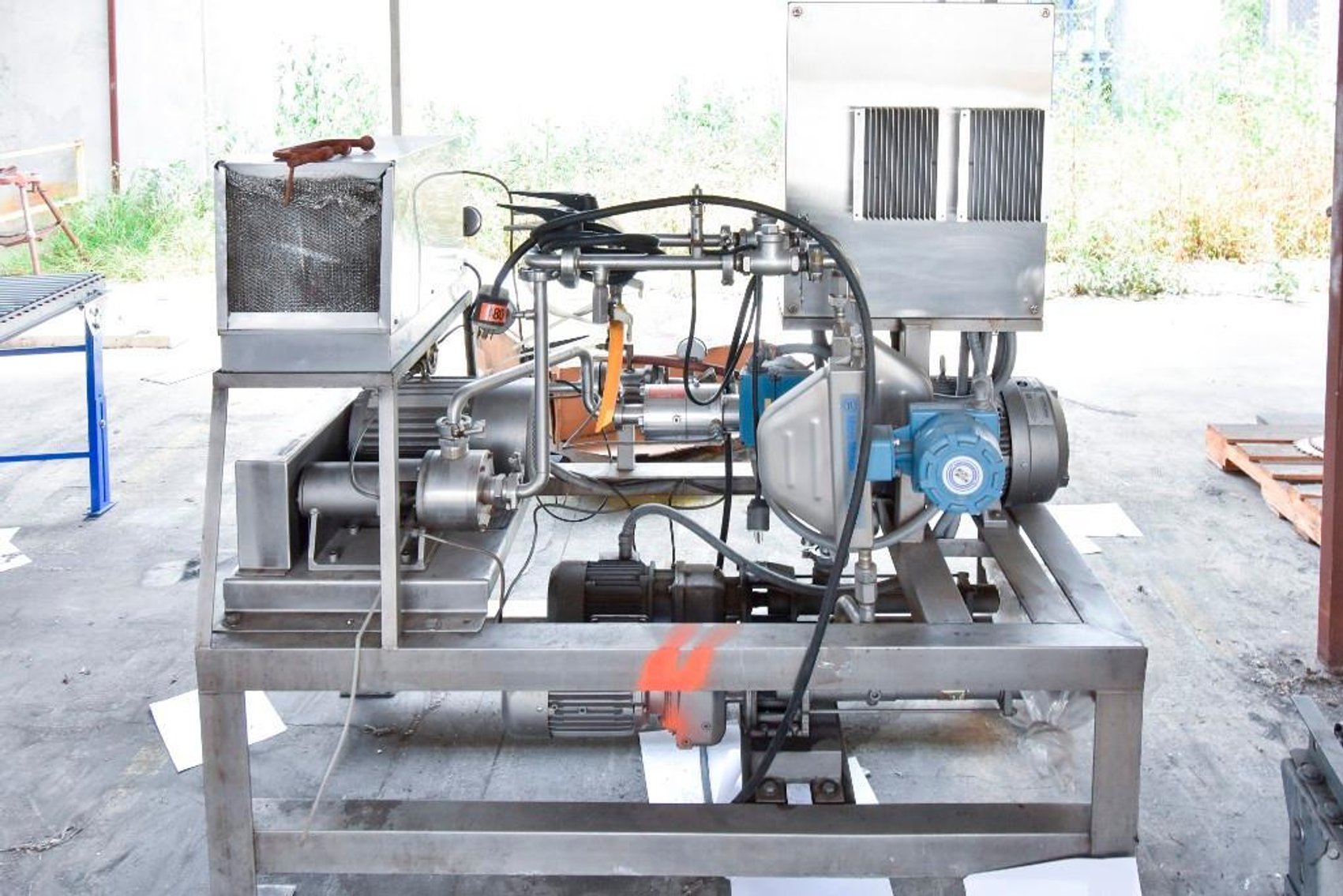

1 - Dispax Reactor DR3 IKA Works

Serial Number: 0635

Description: The IKA DISPAX-REACTOR® DR 2000 is a three-stage high shear inline dispersing machine used for the production of very fine emulsions and suspensions. Shear forces that occur in the working chamber produce a drastic increase of mass transfer and accelerate the dissolving rates of mono and macromolecular substances. Three rotor-stator combinations (generators) in a series ensure small- droplet or particle size and a very narrow distribution spectrum. This process promotes a long stability of mixtures in a single pass, especially when working with emulsions.The DISPAX-REACTOR® inline machine uses shear principles similar to the popular ULTRA-TURRAX® machines UTC and UTL. Minimized volume in the mixing chamber ensures uniform shear on the product.For discontinuous processes, the inline machine DR can be installed with a batch tank or reactor containing the pre-mixed product. When the mixture passes through the dispersing machine, it is homogenized optimally.For continuous processes, the components to be mixed are fed into the machine at an appropriate rate through the inlet connections. Here, the components are thoroughly mixed, dispersed or homogenized within the machine, and then discharged through the outlet.In order to configure the DISPAX-REACTOR® DR to meet a variety of application needs, IKA offers a wide selection of generators. The standard rotor-stator (generator) combination consists of a coarse, medium and fine rotor-stator. When installed in a series, this configuration ensures satisfactory particle size reduction while providing optimum dispersing results in a single pass.The high shear dispersing machine DISPAX-REACTOR® DR 2000 is available in eight sizes. The possible throughput varies from 80 (DR 2000/03) up to 125.000 l/h (DR 2000/50) when using water. All sizes of machines work with the same circumferential speed of the rotor which provides a reliable scale-up.Premier Mill Corp

Serial number: MXS3920760 10098

Model: MXS3

Date: 2000

Voltage: 460

Horsepower: 3

Skidding and Load out charges: There will be loading and skidding charges added to your purchase at market rates for your convenience. Location: Los Angeles, CA Skidding:$480Load Out:$450