Details

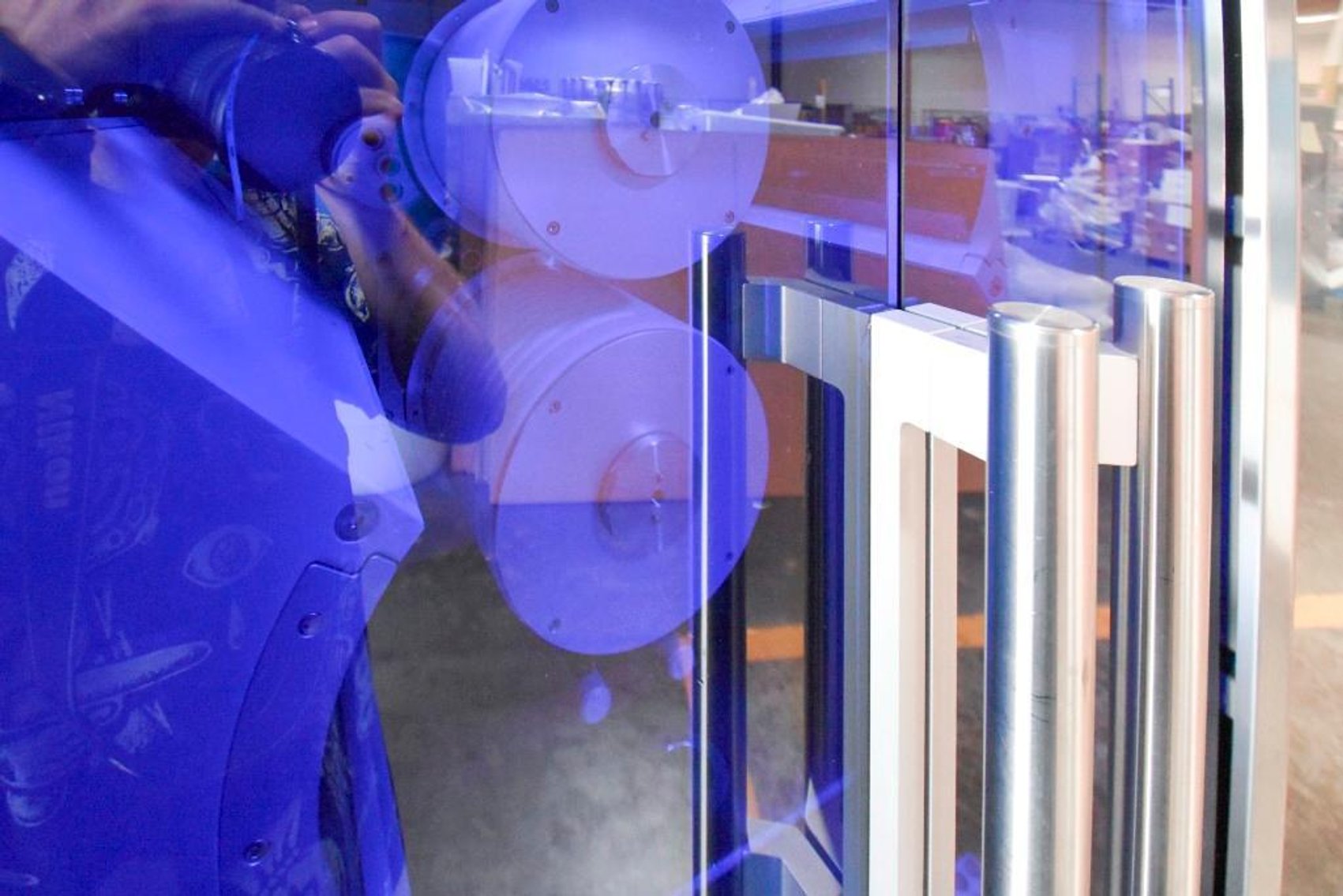

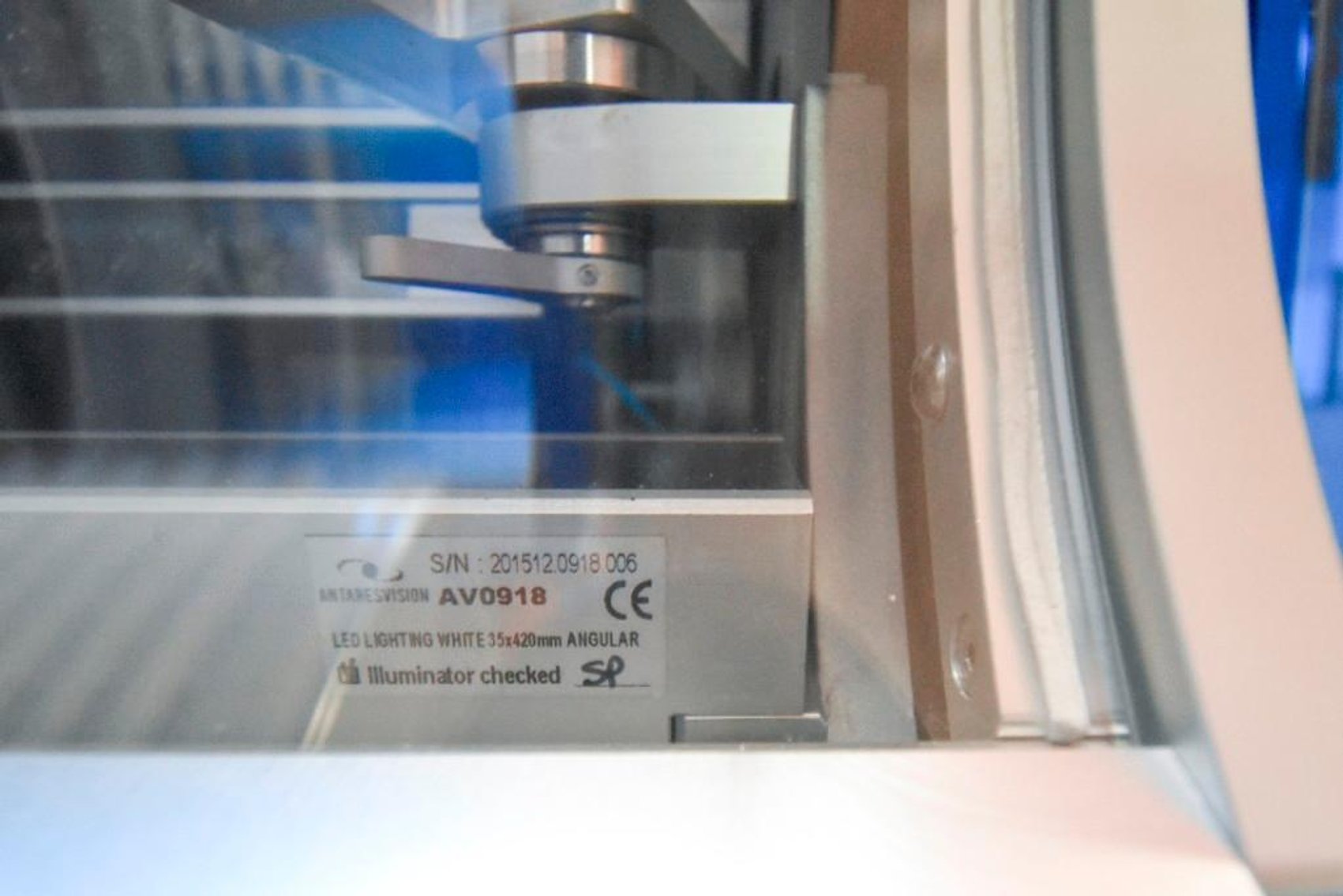

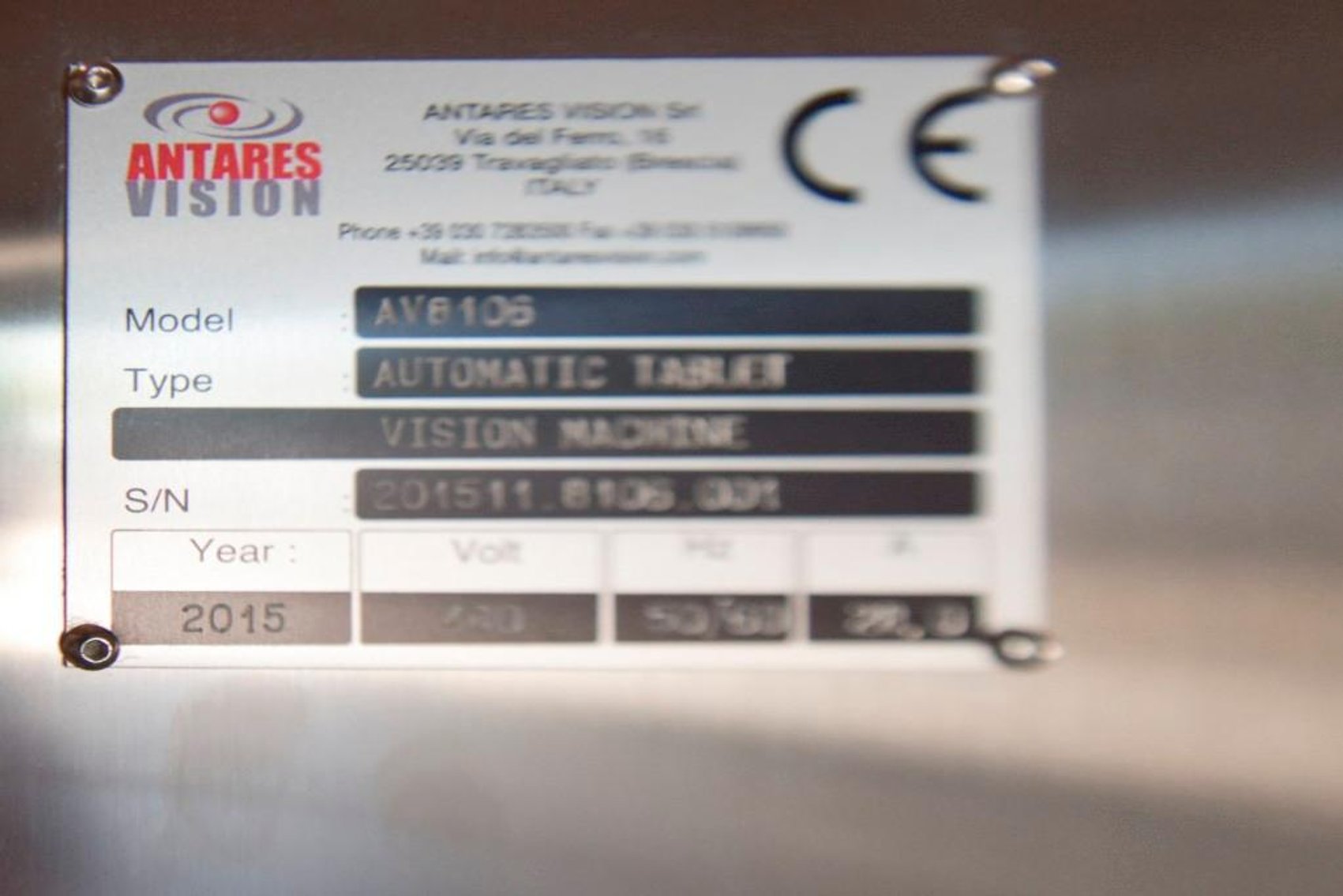

***SOLD*** 1-Antares Vision Machine Model: AVB 106

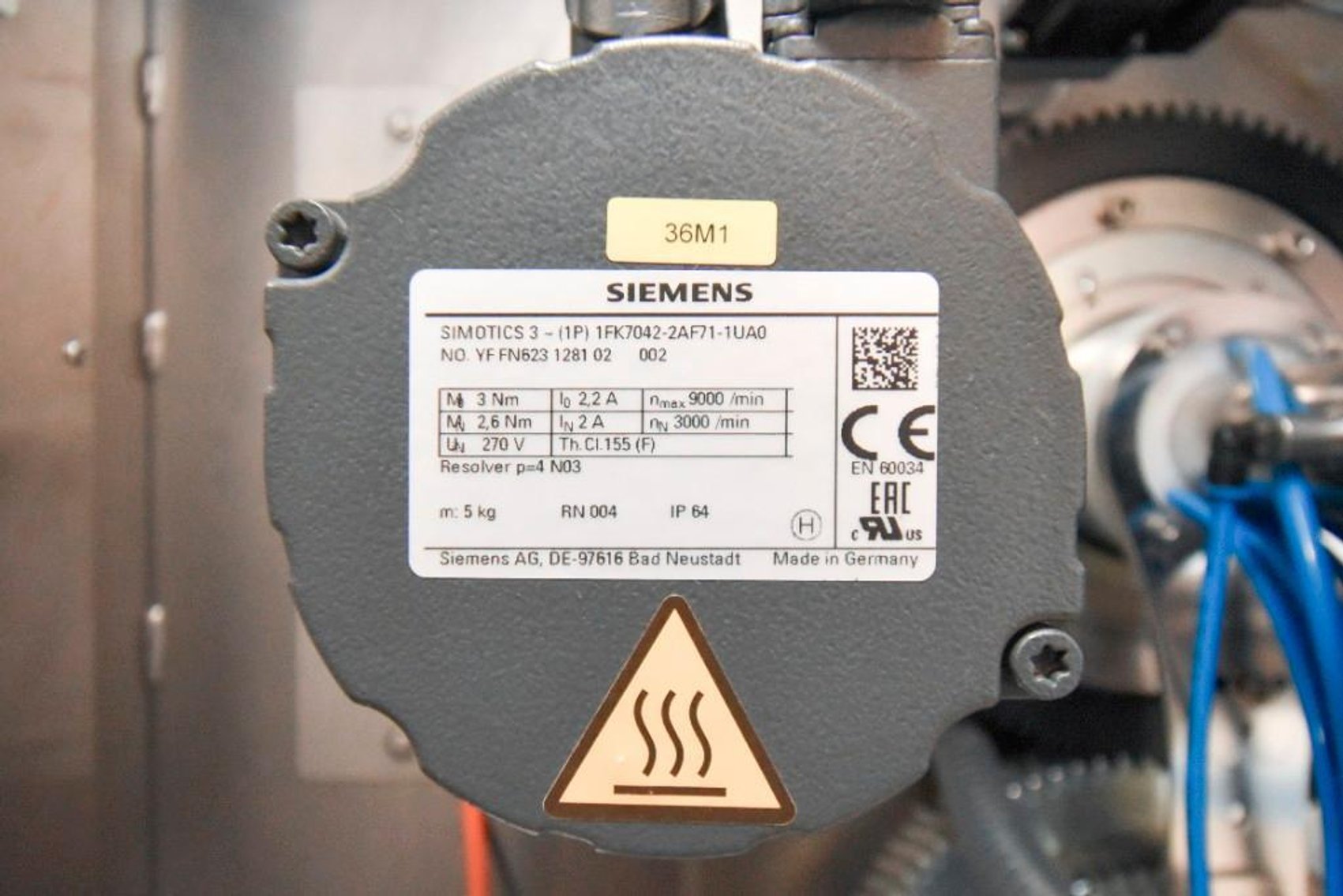

Type: automatic tablet Serial Number: 201511.8106.100 Year: 2015 Volts: 480 Hertz: 60 Amps: 28

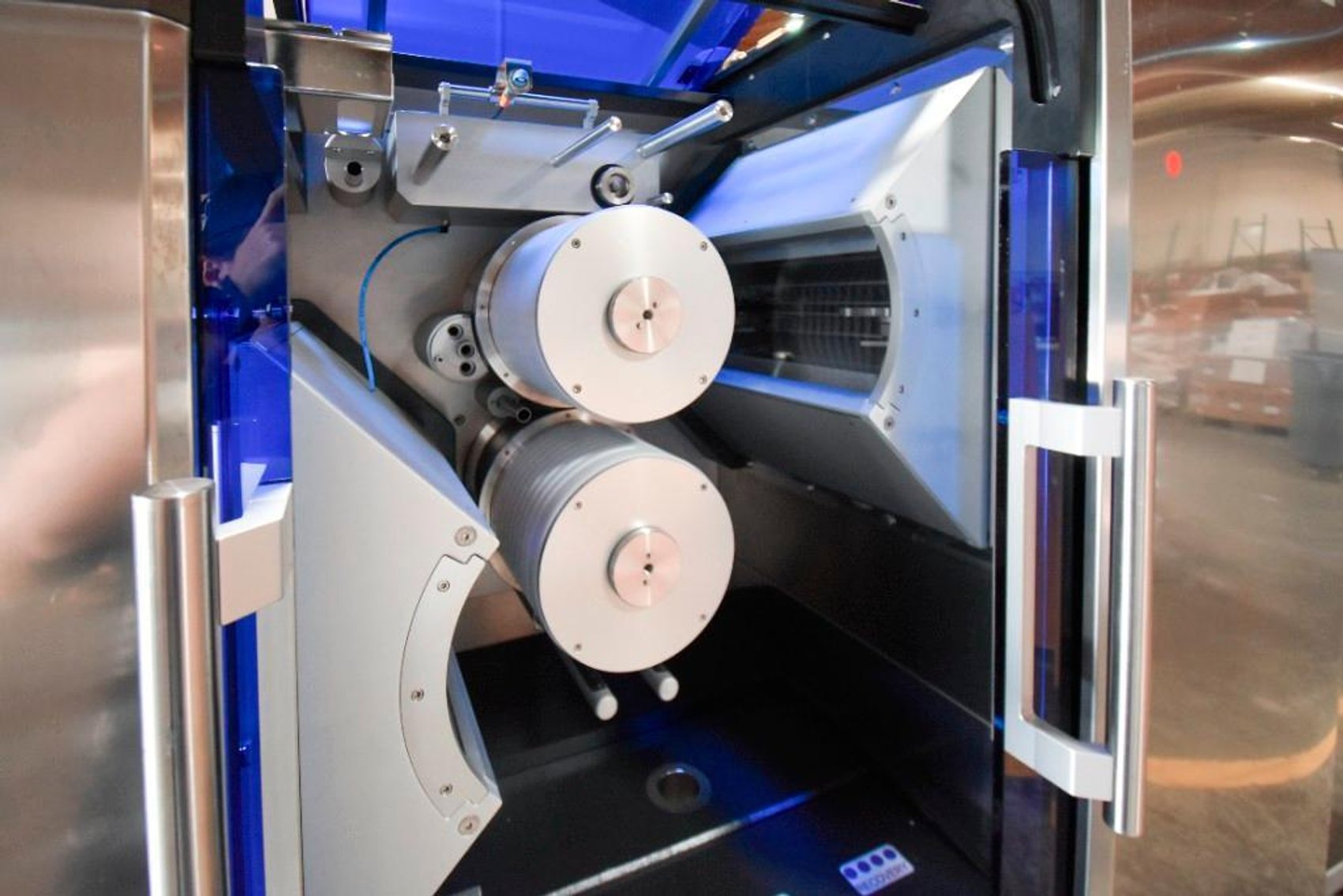

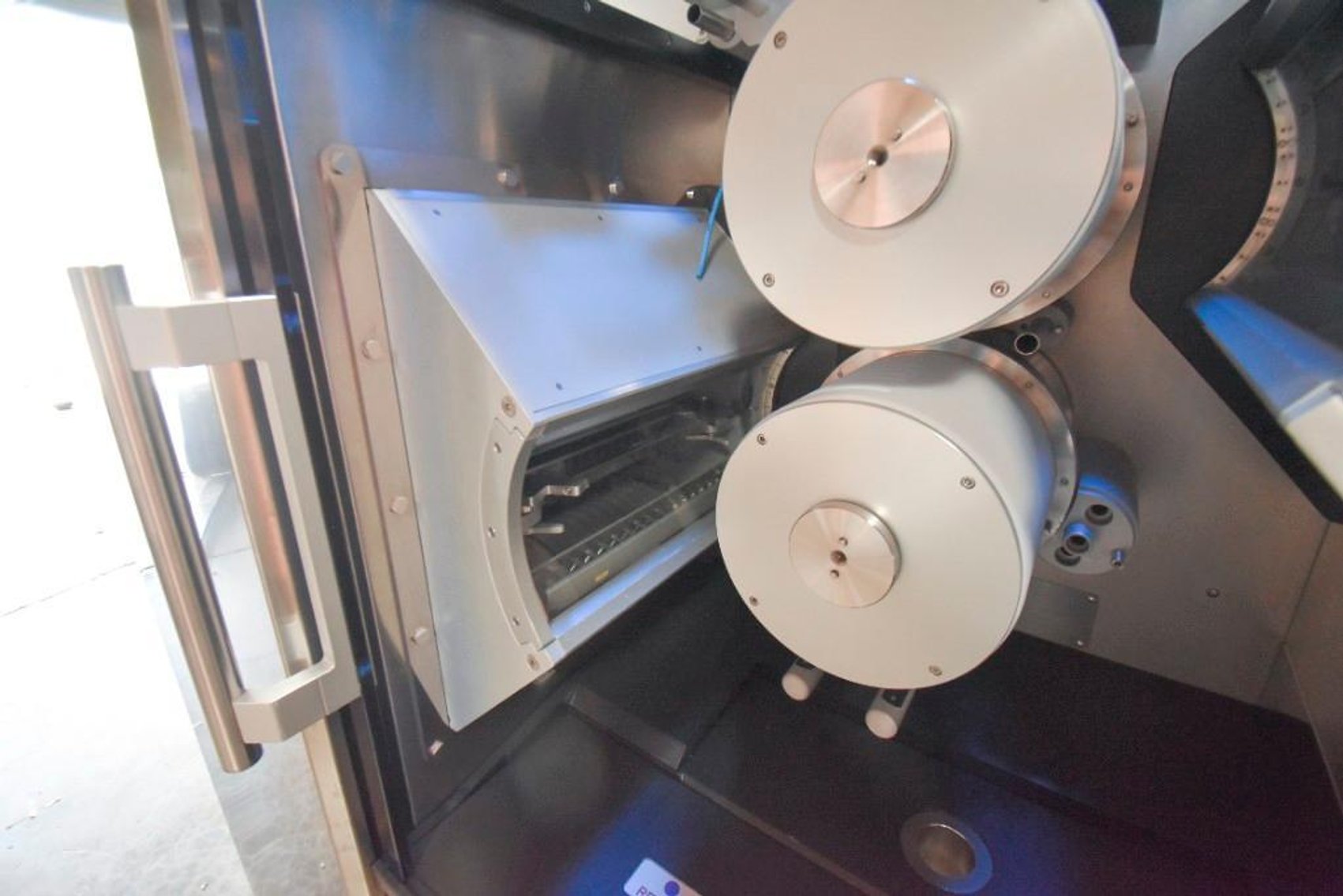

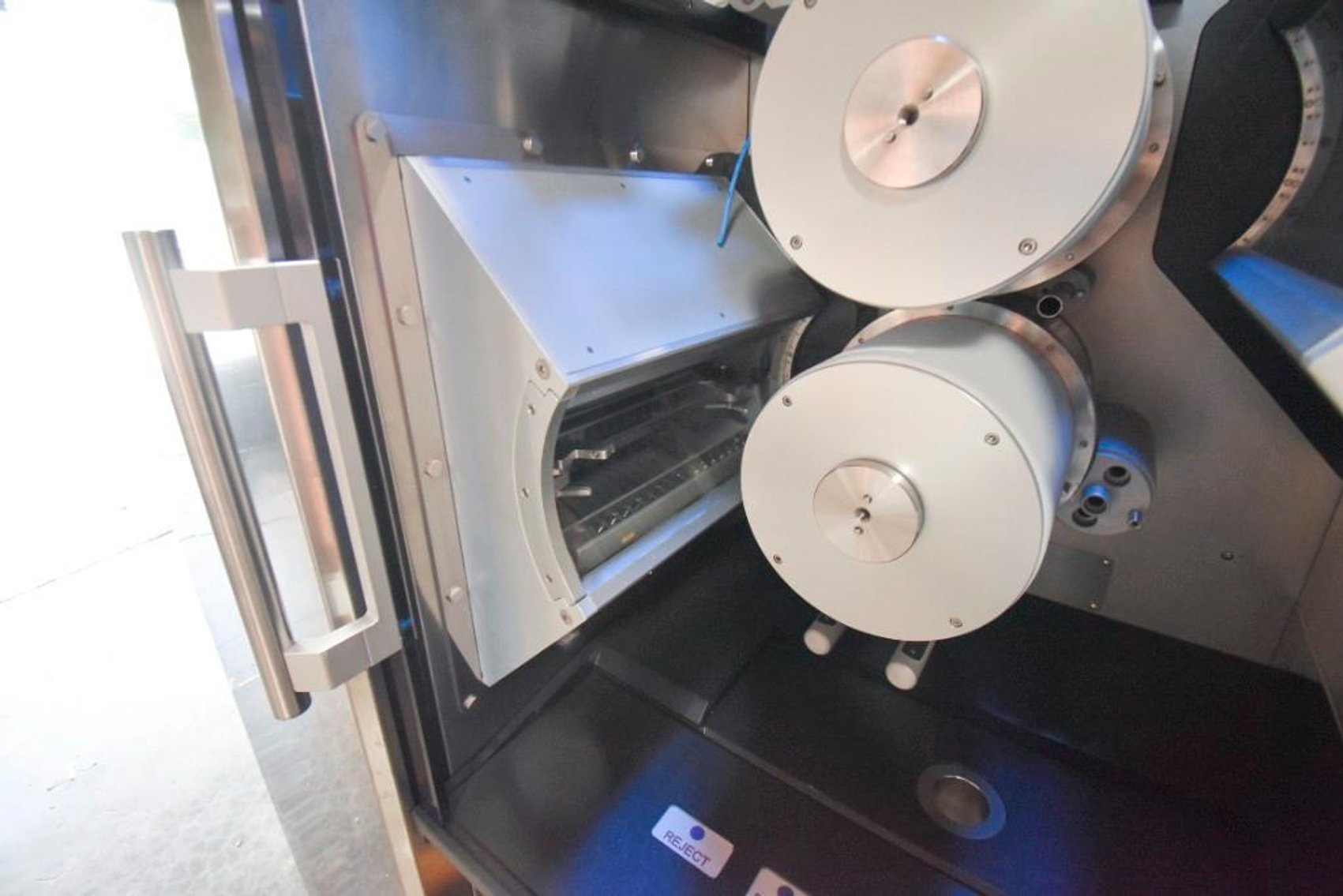

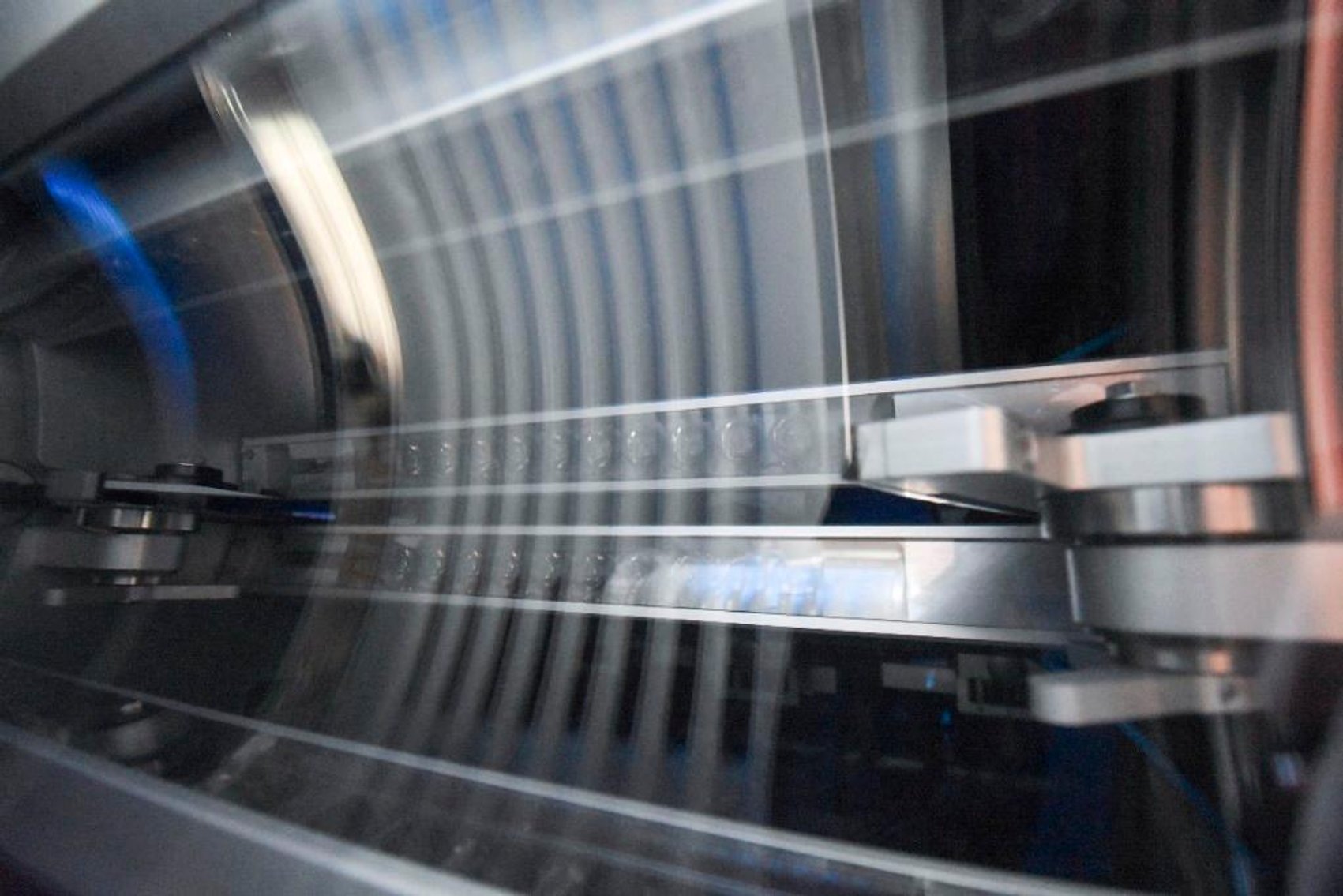

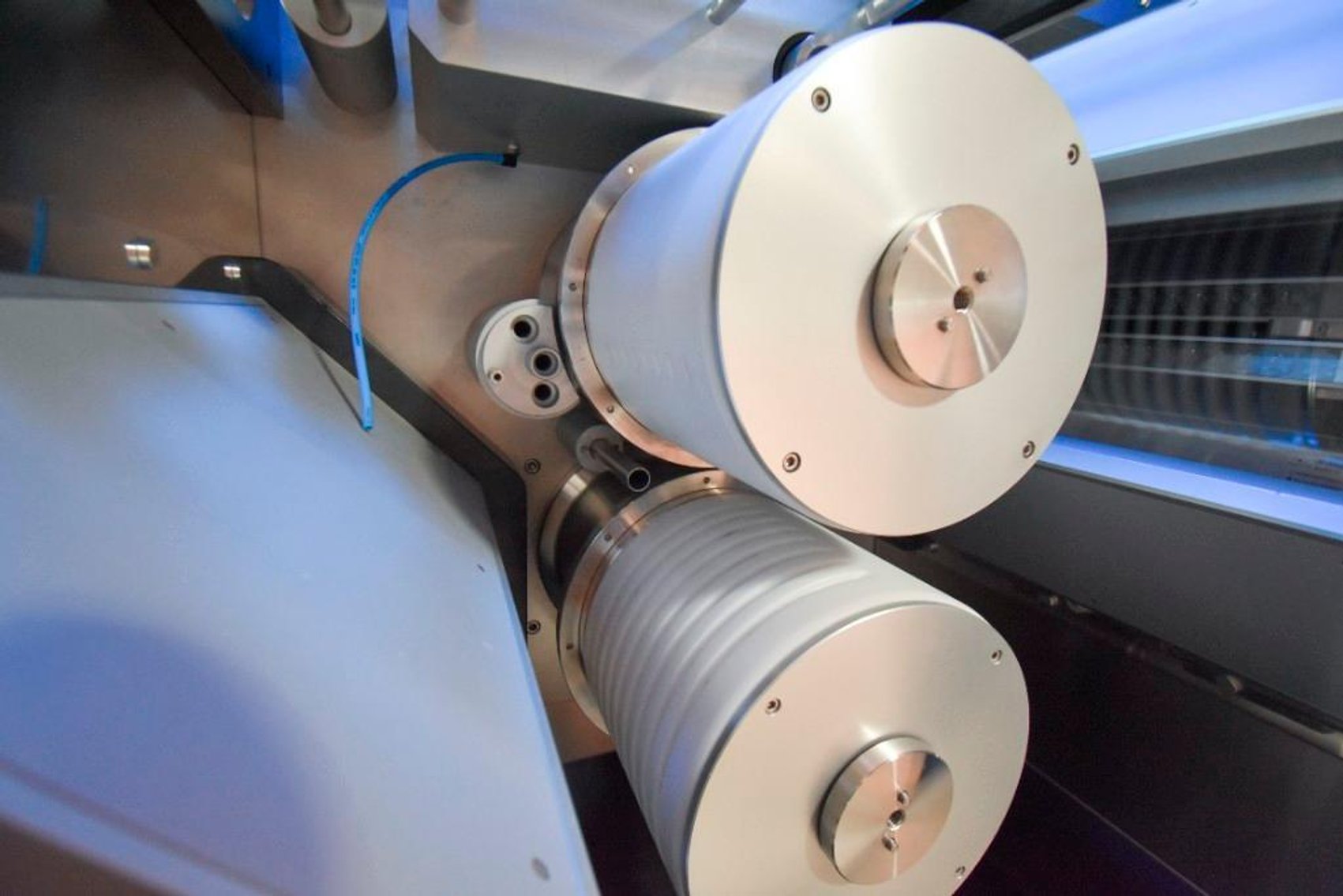

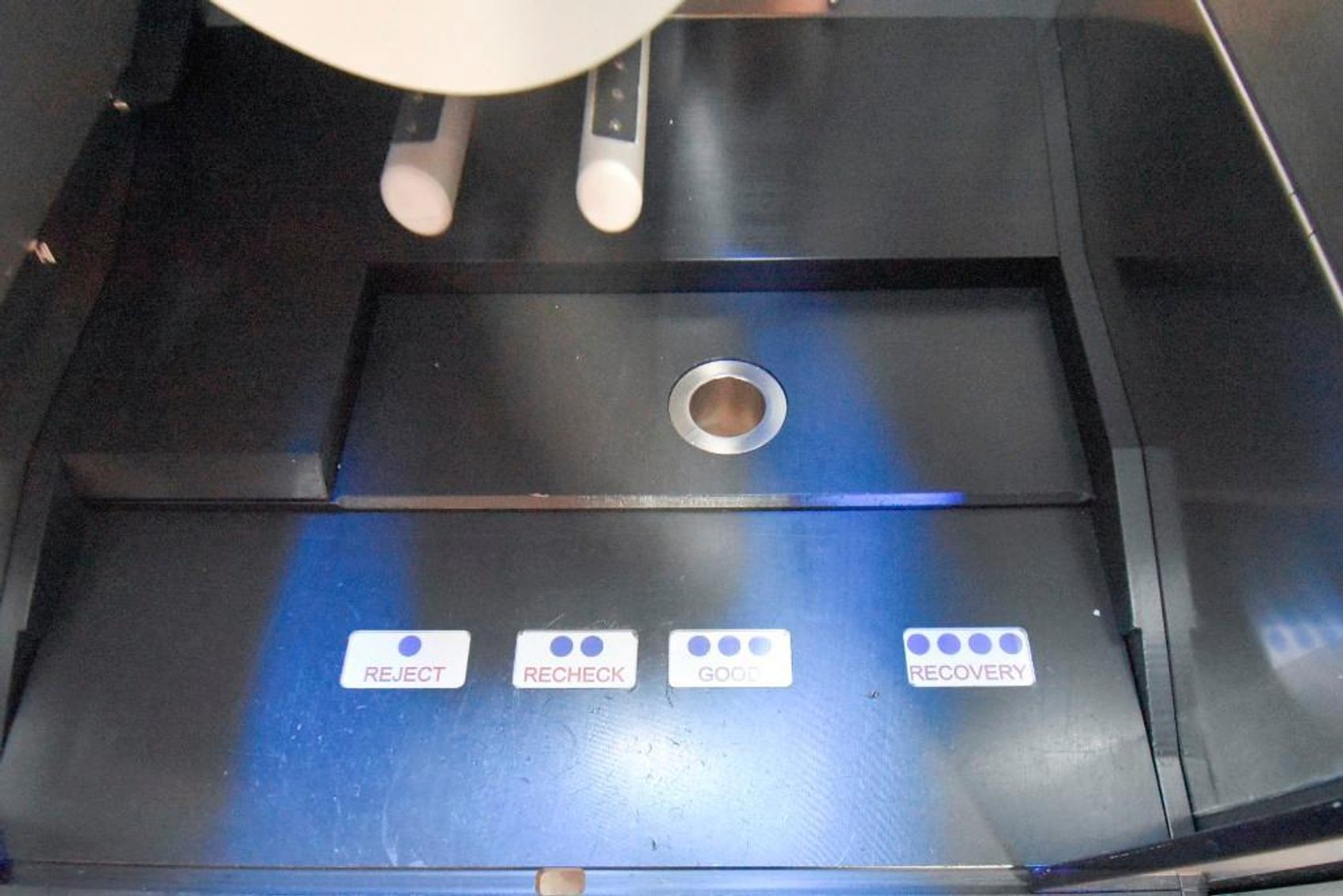

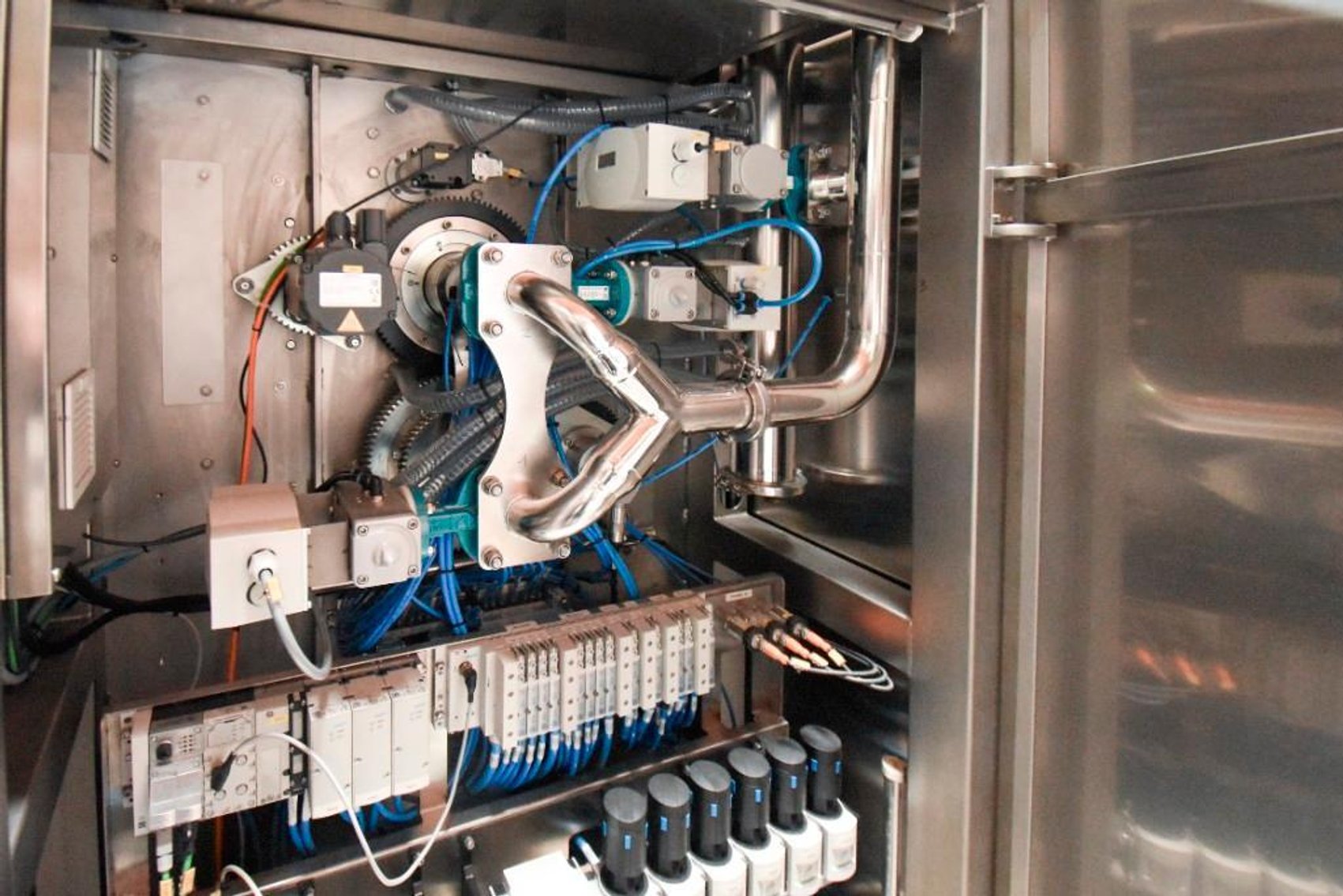

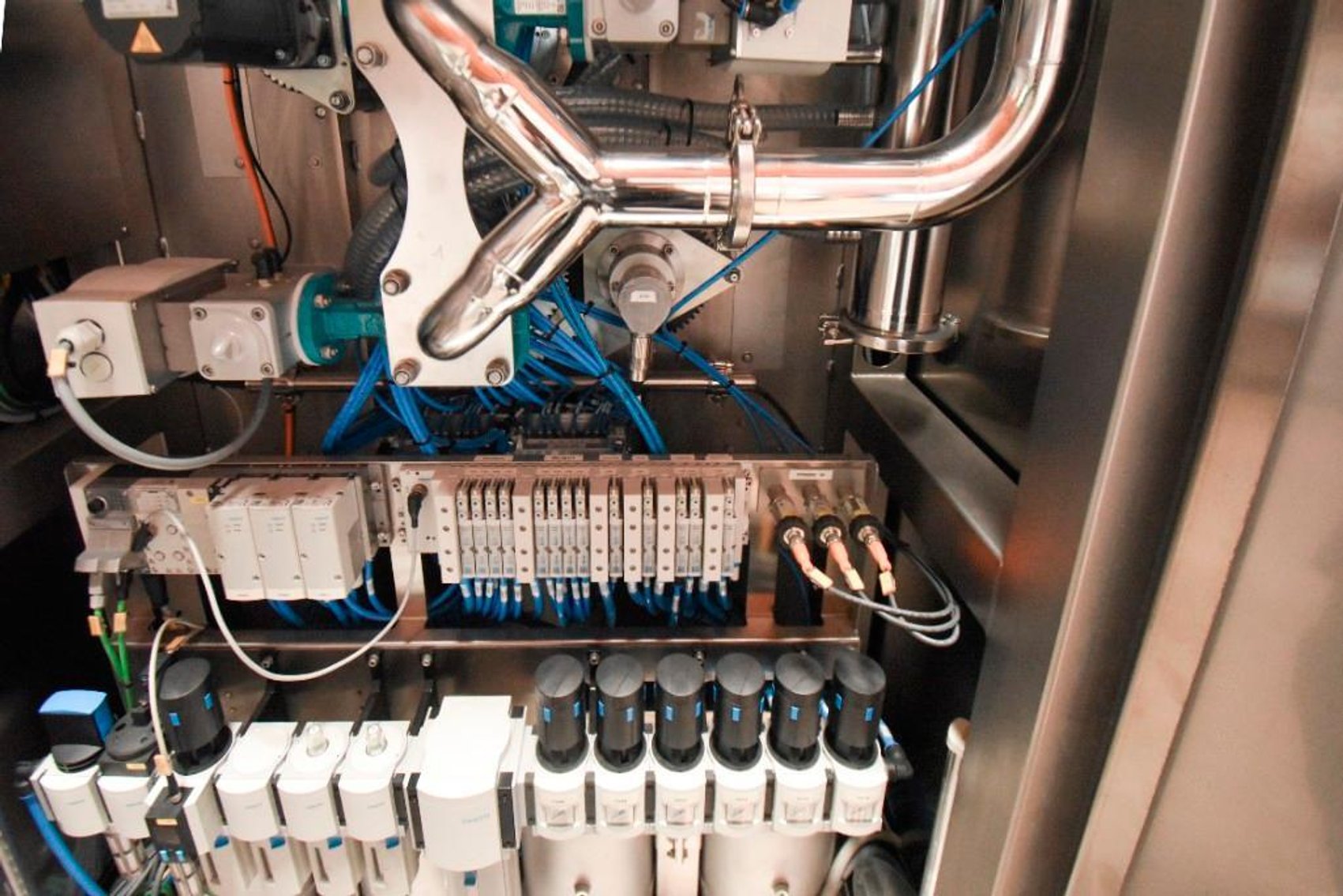

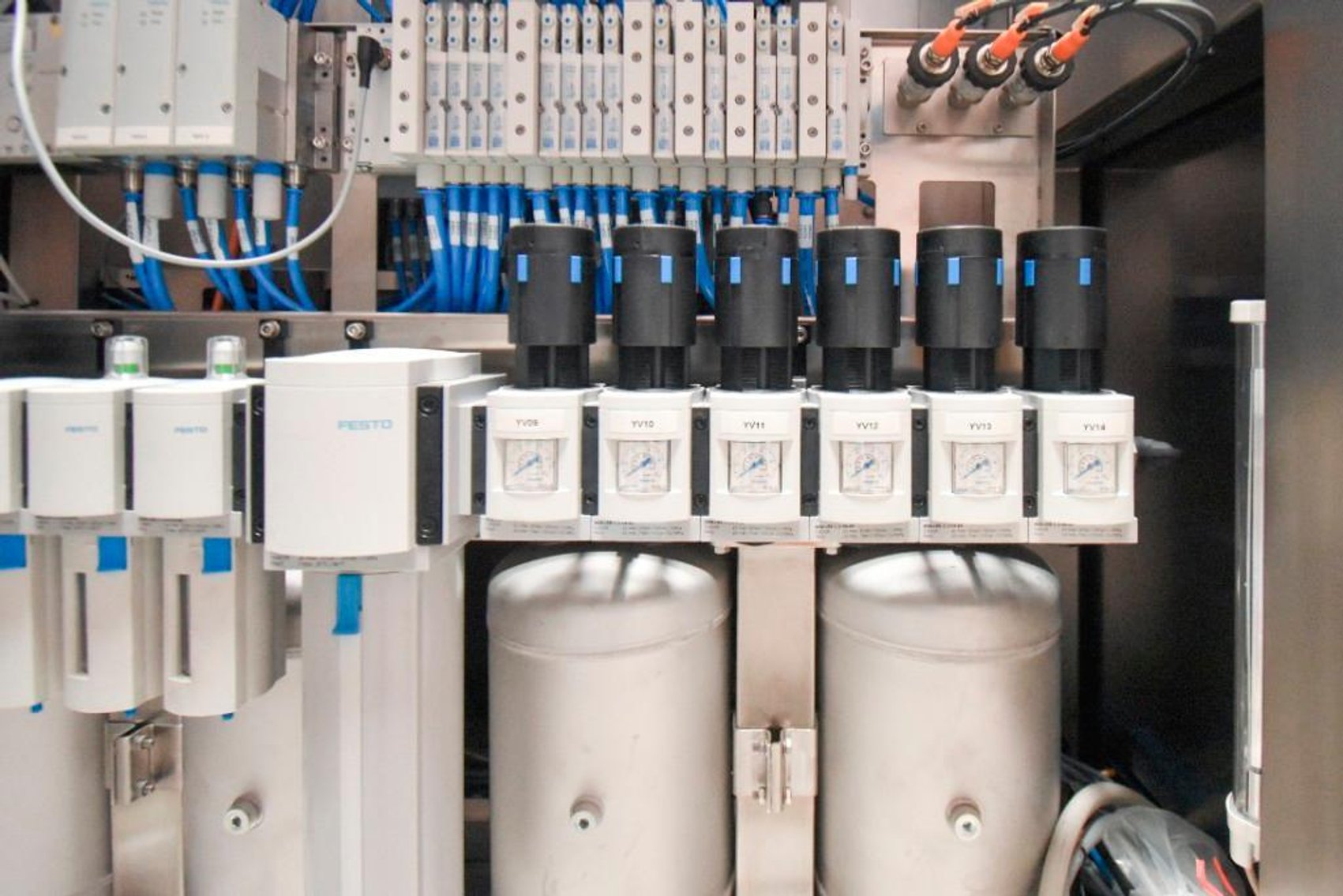

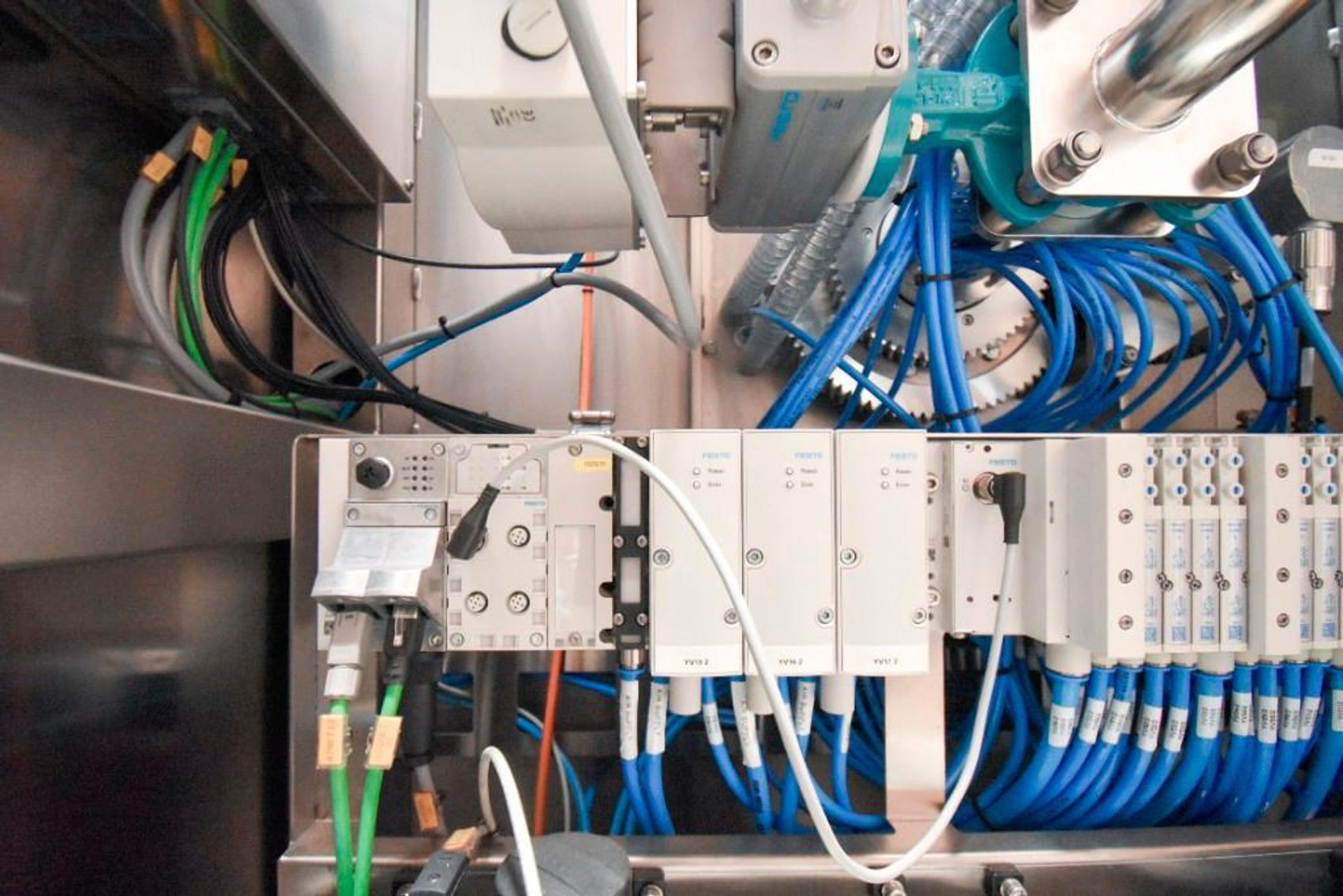

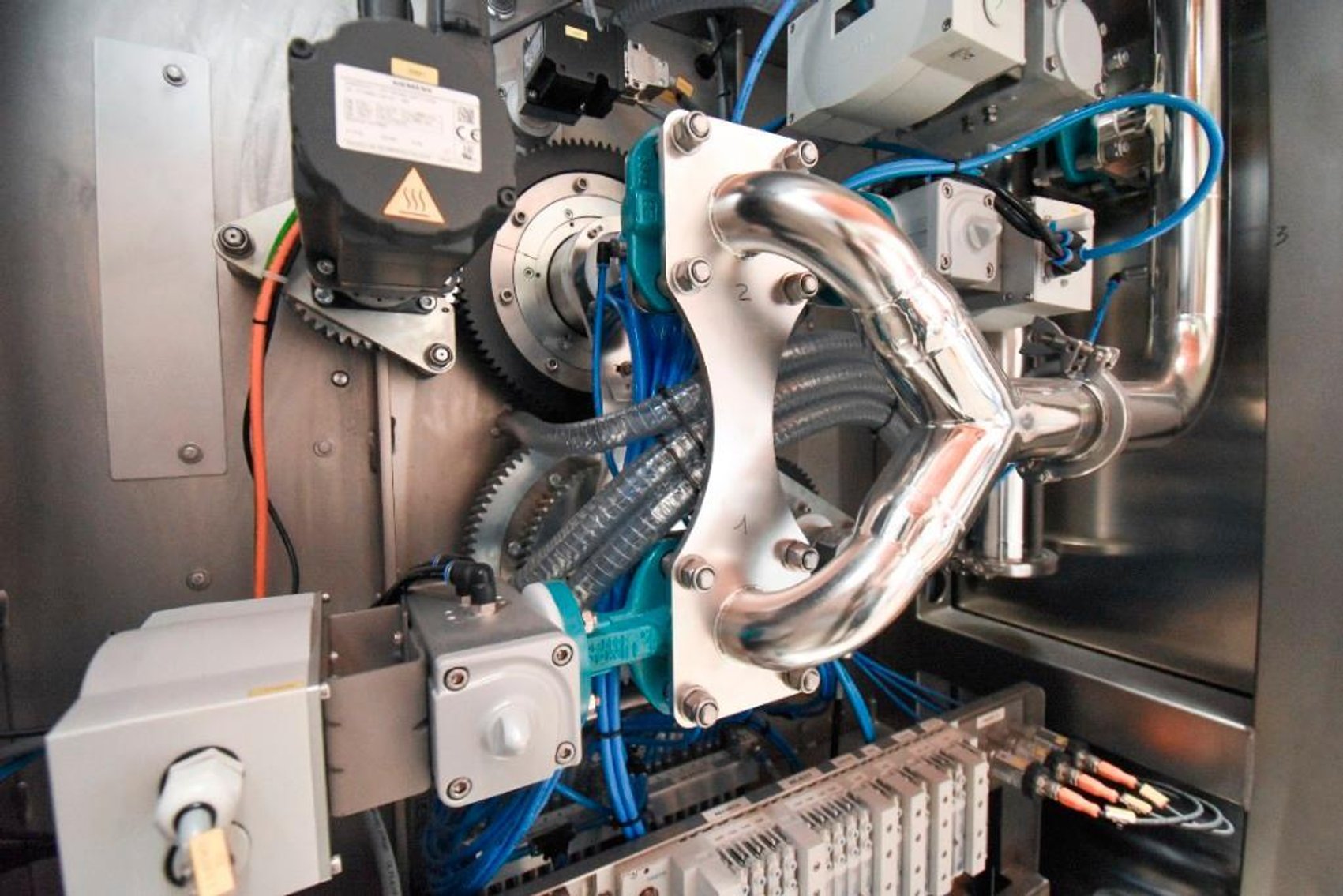

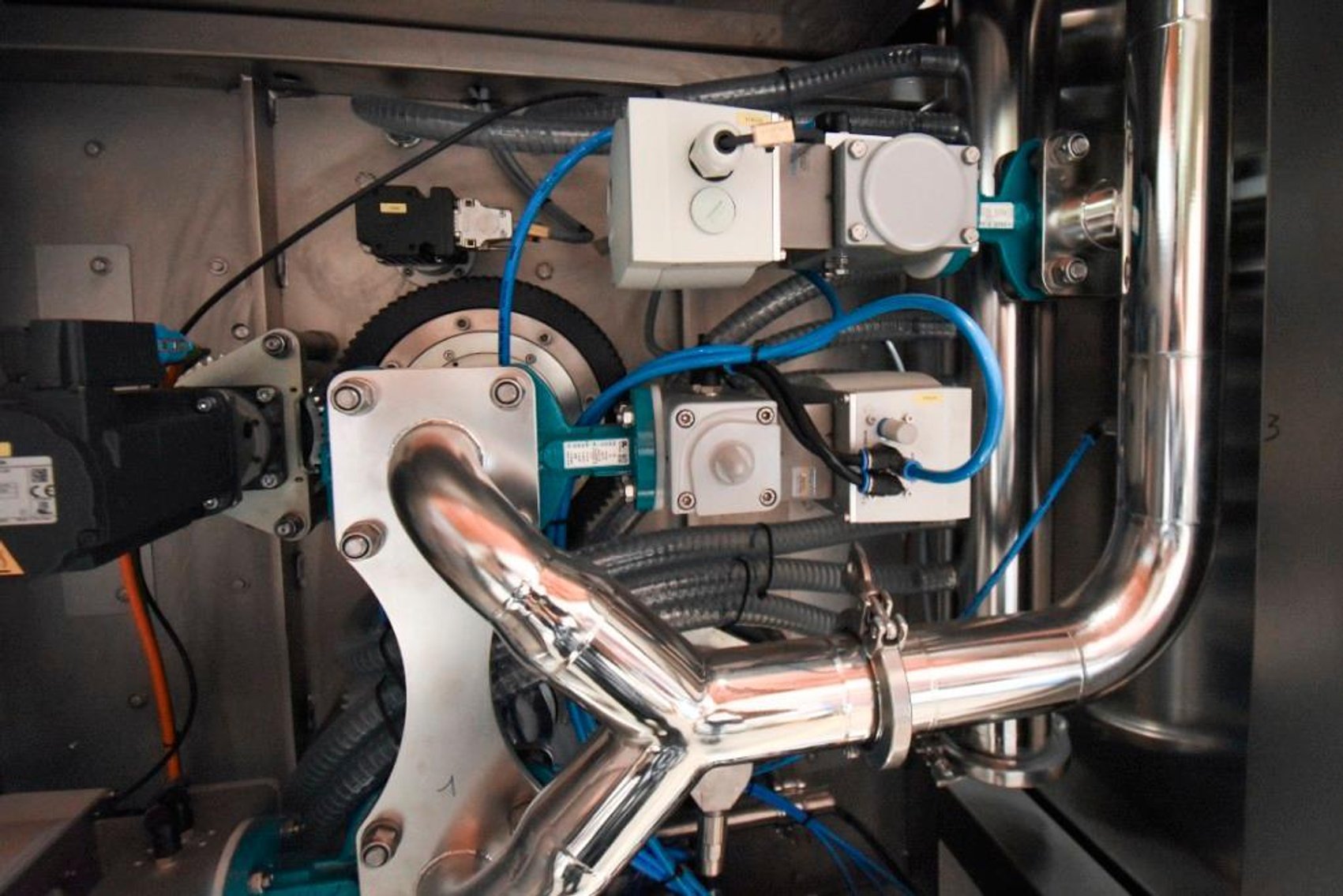

Description: TOTAL DEFECT DETECTION FOR ALL TABLETS AND CAPSULES Automatic Visual Inspection Machines for Tablets & Capsules The Antares Vision Group Tablets and Capsules Inspector is an automatic standalone machine designed to inspect pharmaceutical products at a high throughput up to 300.000 products/hour. An eight channels rotary double-drum system handles products by holding them in position by means of a vacuum system which enables the images to be acquired on the entire surface. Detection of even the smallest defect or imperfection is guaranteed by up to 8 colour high-resolution cameras acquiring up to 16 high-resolution images per product. Wide range of inspections: size discrepancies; shape defects; dots; dirt; cracks; color differences; embossing; coating imperfections; chipped products; printing; holes/drill; dents; joints Continuity: Mechanical handling is not sensitive to dimensional variations, providing continuous automatic inspection even in case of highly variable products Easy to use and user friendly: quick format changeover, manageable by up to 5 user login levels, easy cleaning procedure and maintenance Efficient: provides advanced statistical analyses with visual defect-detection feedback, and detailed reject typology to help identify the reject causes.

Skidding and Load out charges: There will be loading and skidding charges added to your purchase at market rates for your convenience. Location: Los Angeles, CA