Details

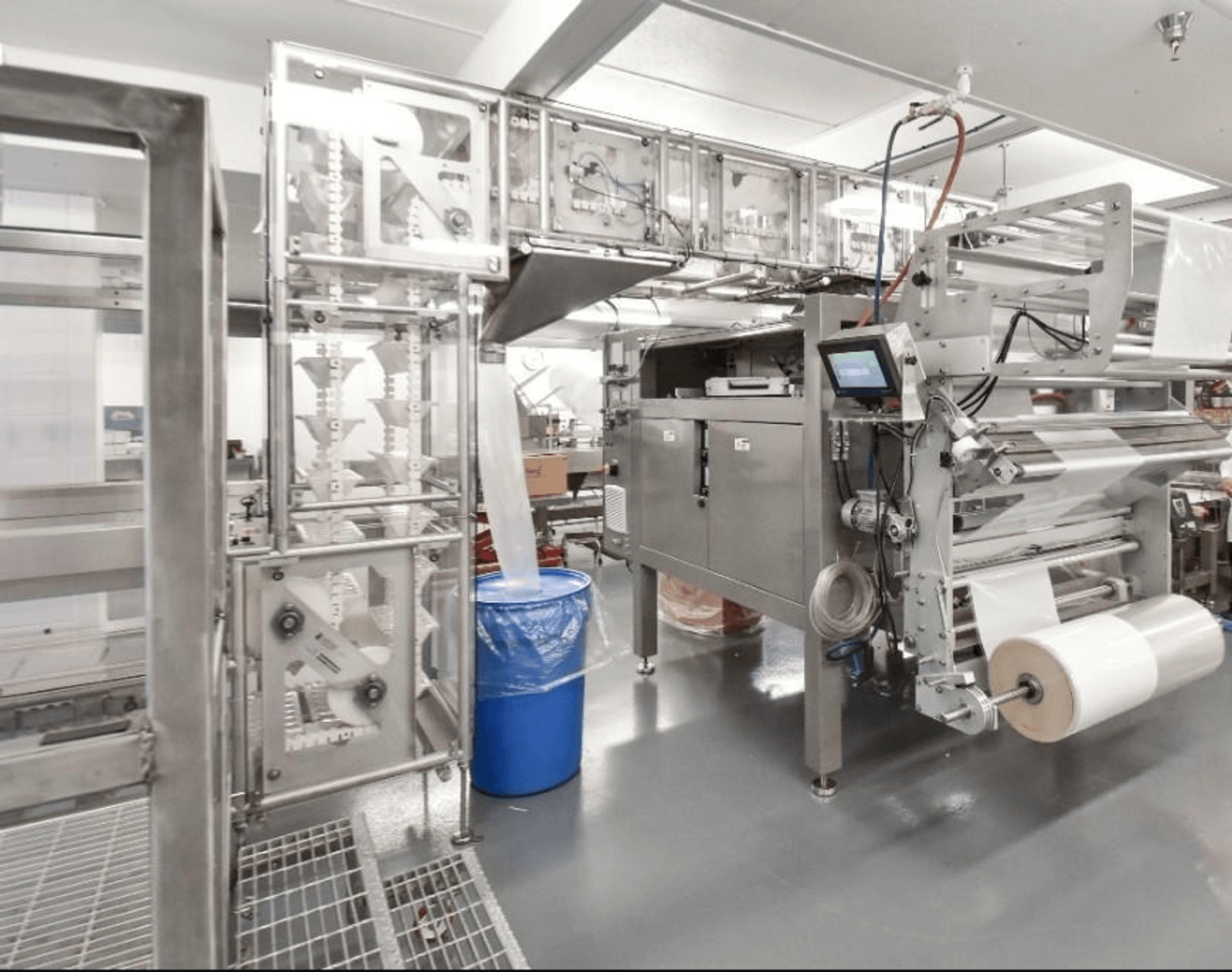

1- Viking Masek Multi Lane SA600D Packet/Sachet Filling Line

*Equipment was used for only one shift, running three different product configurations. Average batch size ran was 3K but the engineering of the machine is designed for much larger batches.

Condition

New 2017 – Like New

Lightly used (only one shift of production)

Ran three different product configurations

Average batch size ~3,000 units (machine engineered for much larger runs)

All manuals, schematics, and drawings available electronically

System Overview

The Viking Masek Multi Lane SA600D Packet/Sachet Filling Line is a fully integrated, high-speed sachet packaging system with bulk loading, counting, form-fill-seal sachet packaging, in-line printing, metal detection, and automated cartoning. It is designed to handle powders, granules, liquids, semi-liquids, and particulates into flexible sachets, with secondary packaging into cartons or caddies.

Key Specifications

Output: 20–60 cycles per minute (functional), up to 80 cycles/min (test run without product)

Bag sizes:

Length: 50–200 mm

Max tube diameter: 28 mm

Packaging films: heat-sealable, including:

Paper/PE (45/15 microns)

12PET/9Al/40PE

12PET/70PE

12PET/12Al/50LDPE

Film reel capacity:

Max reel diameter: 500 mm

Max reel width: 1260 mm

Reel core: 70–76 mm

Machine Identification

Sachet Machine – Viking Masek SA600D

Model: SA600D

Serial No.: 4743

Electrical: 3x480 V, 27 A, 60 Hz

Multi-lane capacity: 1–10 lanes

Capable of producing 4-side sealed sachets with options for tear notches and easy-open systems

Designed for powders, dense/fine/loose particulates, as well as liquids and semi-liquids

Carton Packing Machine – Viking Masek CFM

Model: CFM-B/1/G-30

Serial No.: 4774

Electrical: 230/400 V, 30 A, 30 Hz

High-performance carton erector capable of running single, double, or triple head operation

Handles multiple carton shapes with flexibility and efficiency

Additional Viking Masek CLM-1/G-30 (Support Equipment)

Model: CLM-1/G-30

Serial No.: 4746

Production Year: 2017

Electrical: 230/400 V, 32 A, 24 VDC, 60 Hz, 9 kVA, IP44

System Components

Bulk Loading & Counting

Pharma Packaging Systems (PPS) Feeder with 7 stainless bulk hoppers

6 vibratory bowls, programmable to dispense 1–6 units each

Precision counting sensors feeding product to bucket conveyor

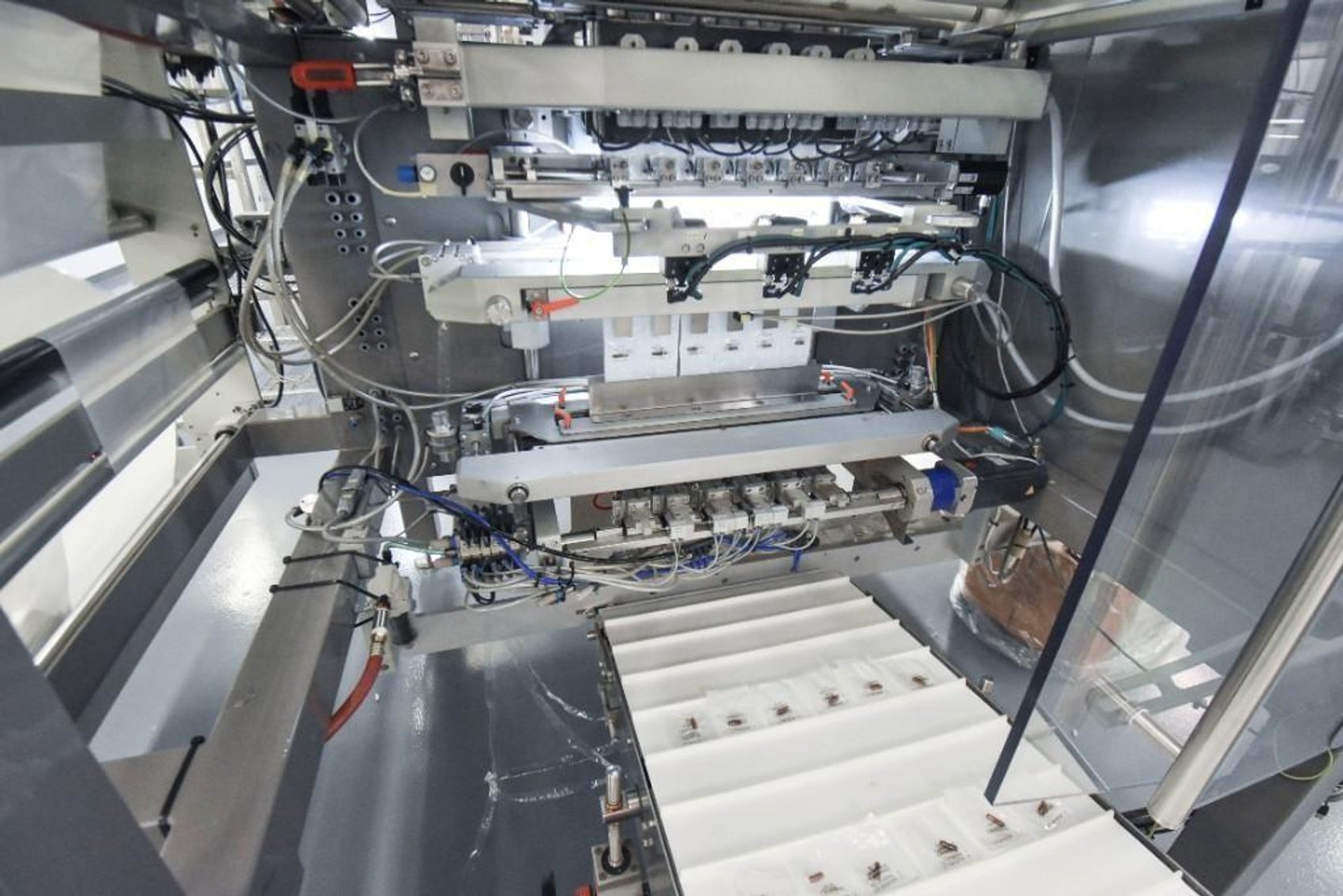

Sachet Filling & Sealing (SA600D)

Multi-lane vertical packaging machine (1–10 lanes)

Flexible dosing systems:

Volumetric (crystalline products – sugar, salt)

Screw doser (powders)

Piston doser (liquids, pastes)

Upgraded sealing block and slitter blades

Integrated in-house product drop system (patent included)

Three Smart Date X65 printers (each handling two lanes for logos, codes, and variable data)

Product Inspection

Thermo Scientific APEX metal detector (Part# 085381) – inline with cleated conveyor after fill

Cartoning & Case Handling

Masek Carton/Cadi Loader: robotic head counts and loads pre-set number of sachets into cartons/caddies

Masek Carton/Cadi Former (CFM-B/1/G-30): five die sizes, hot melt glue applicator (Nordson ProBlue), suction arm feeder for blank or printed cartons, multi-head operation

Masek Carton/Cadi Closer: Viking glue-down sealing station, adjustable for multiple carton widths/heights

Highlights

Turnkey sachet-to-carton line with feeding, counting, sachet forming, printing, inspection, cartoning, and sealing.

SA600D sachet machine: 1–10 lanes, flexible formats, supports powders, particulates, liquids, and pastes.

CFM carton packer: versatile erector with single/double/triple head capability.

High accuracy, efficiency, and adaptable batch sizes.

Like-new condition with full traceability (serials and nameplates).

Skidding and Load Out Charges: Loading and skidding charges will be added to your purchase at market rates for your convenience.

Location: Lehi, UT Skidding: TBD Load Out: TBD