Details

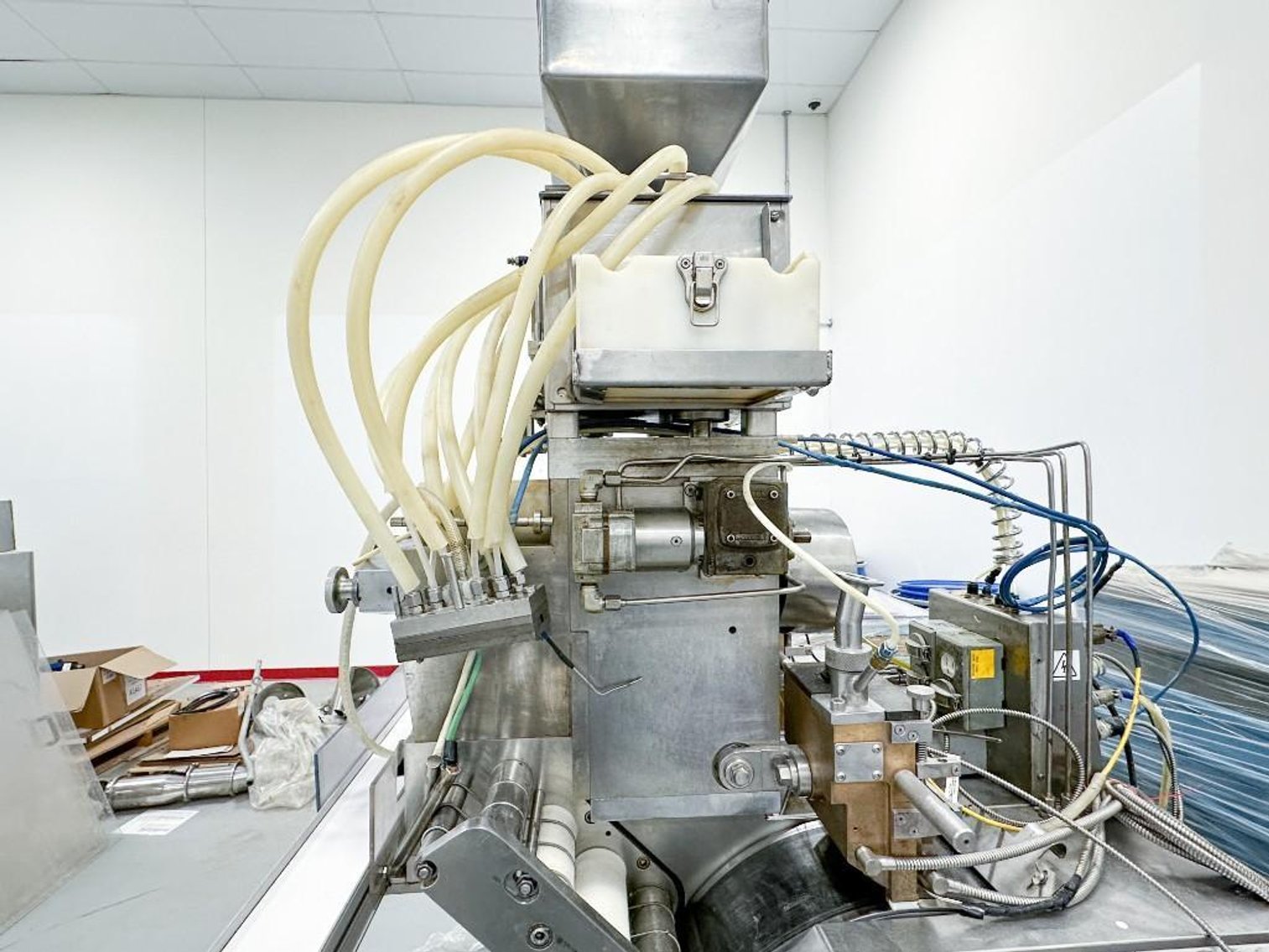

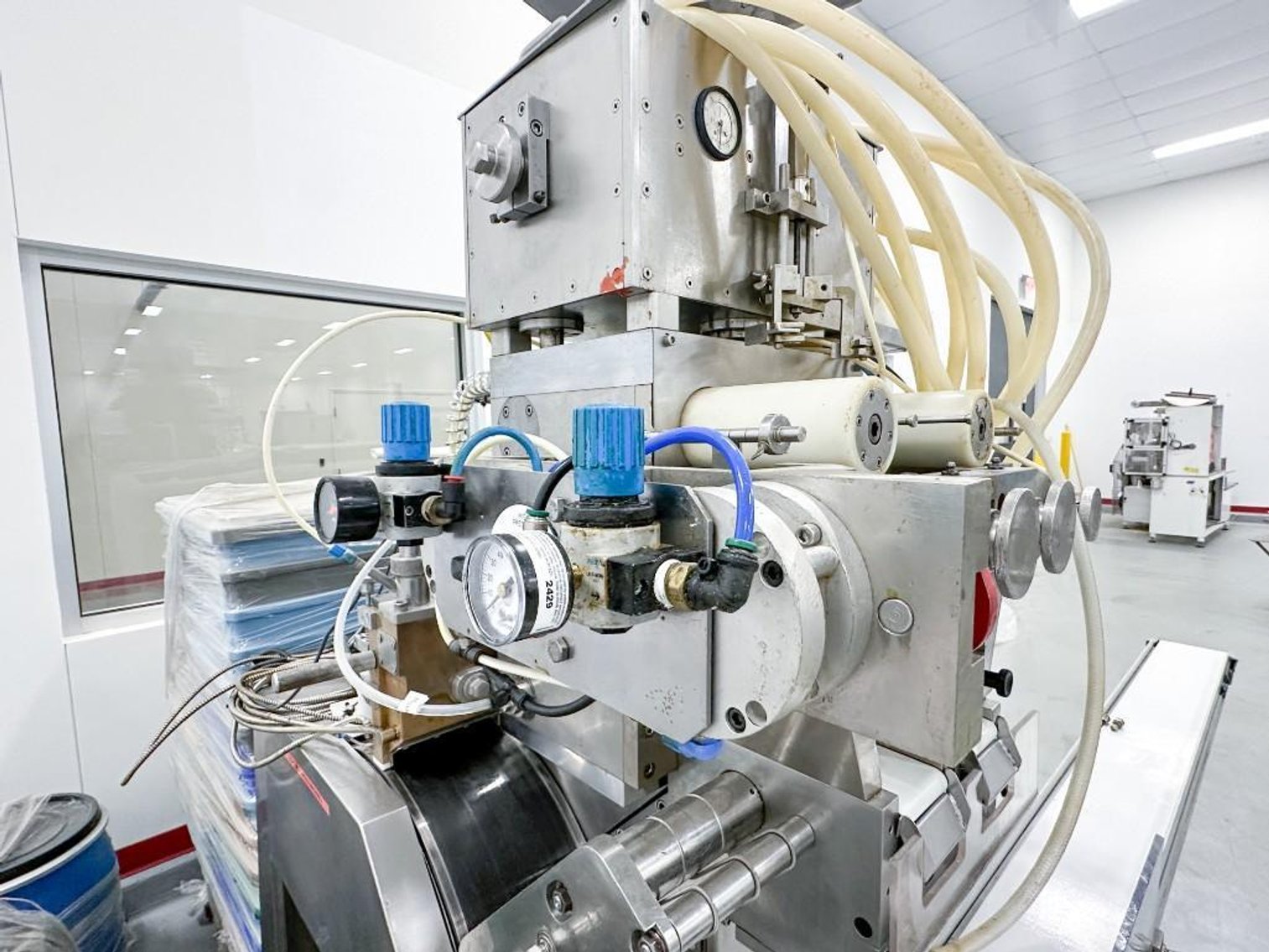

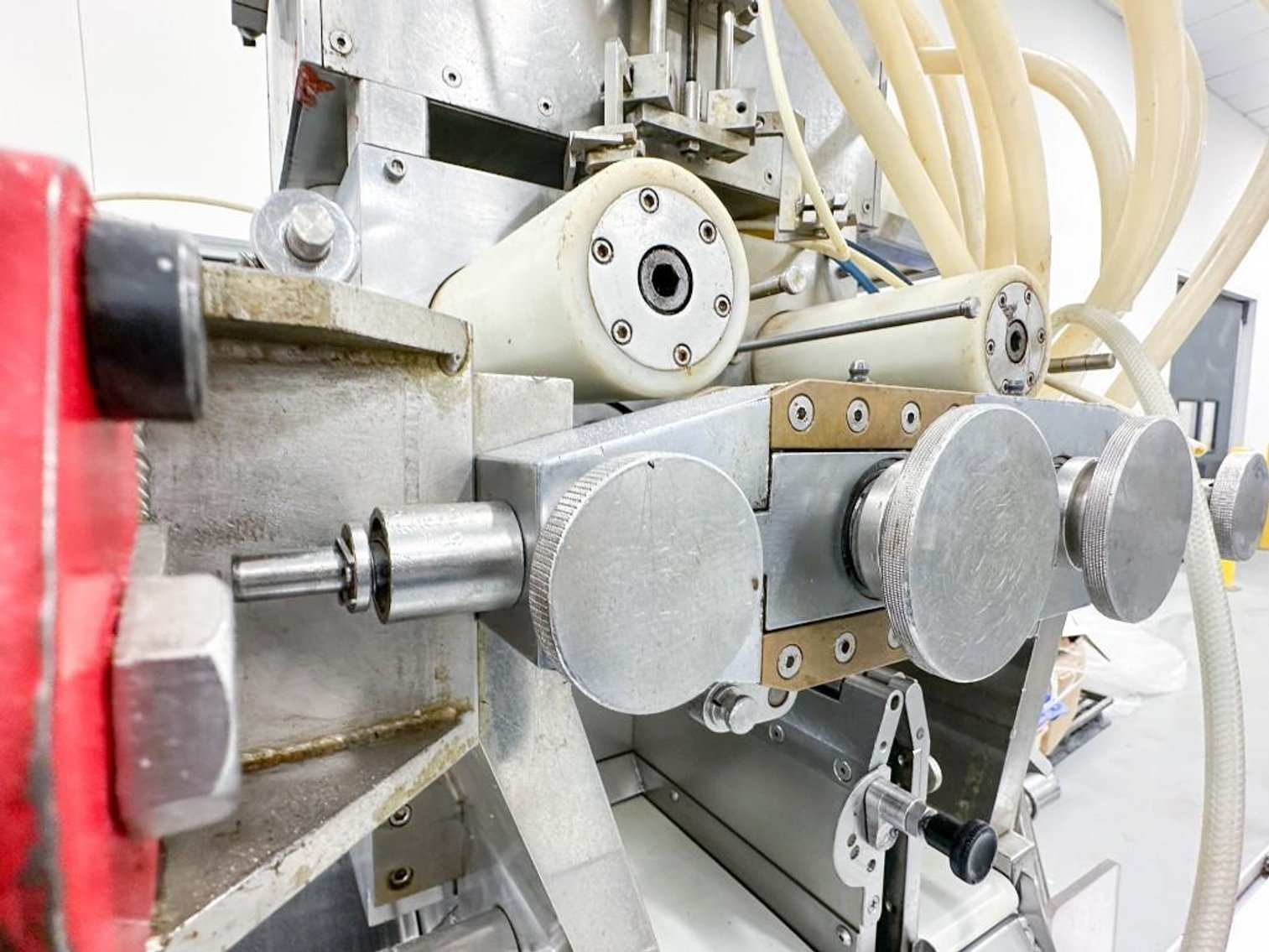

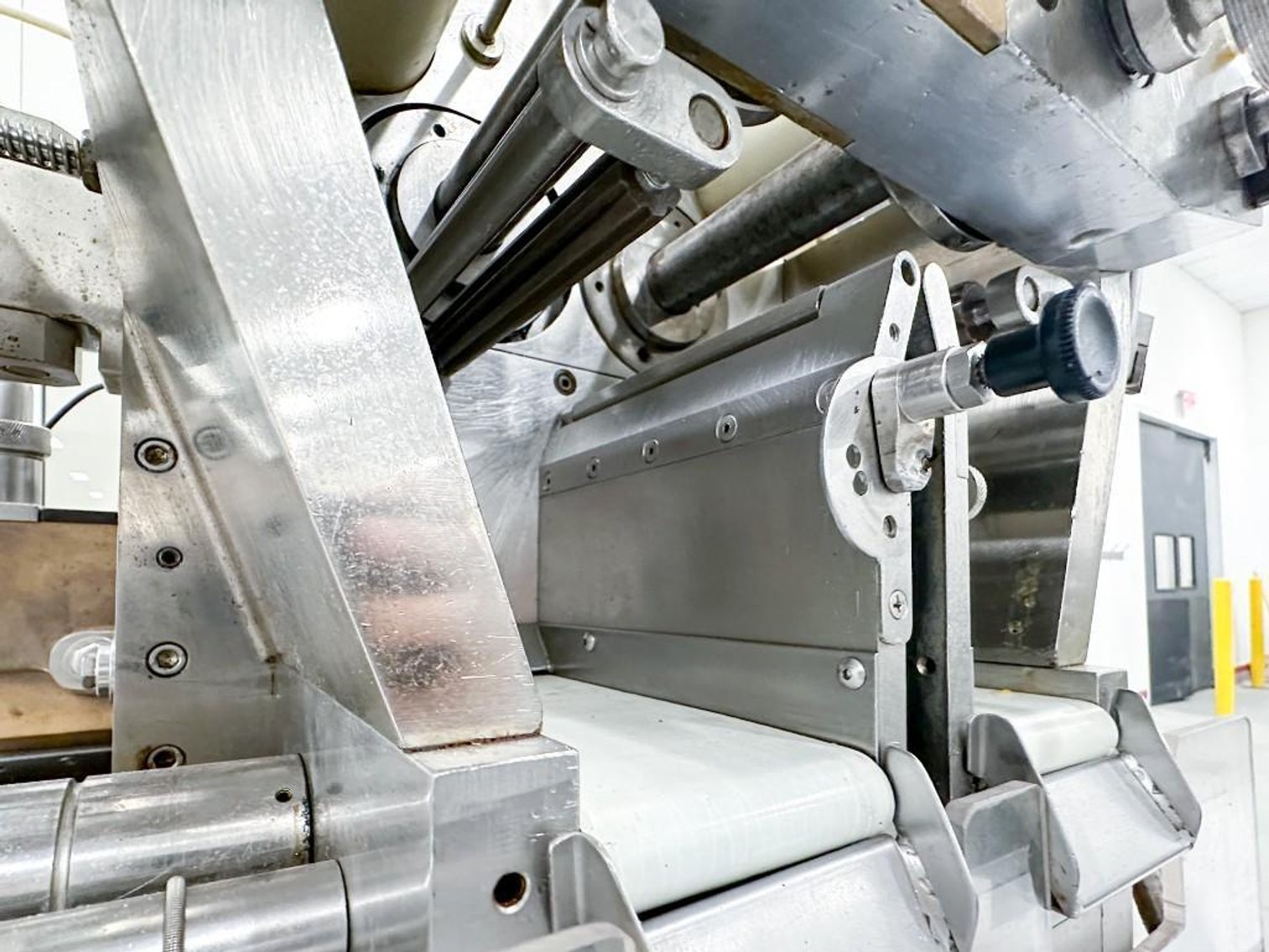

1- Pilot Soft Gel Capsule Machine

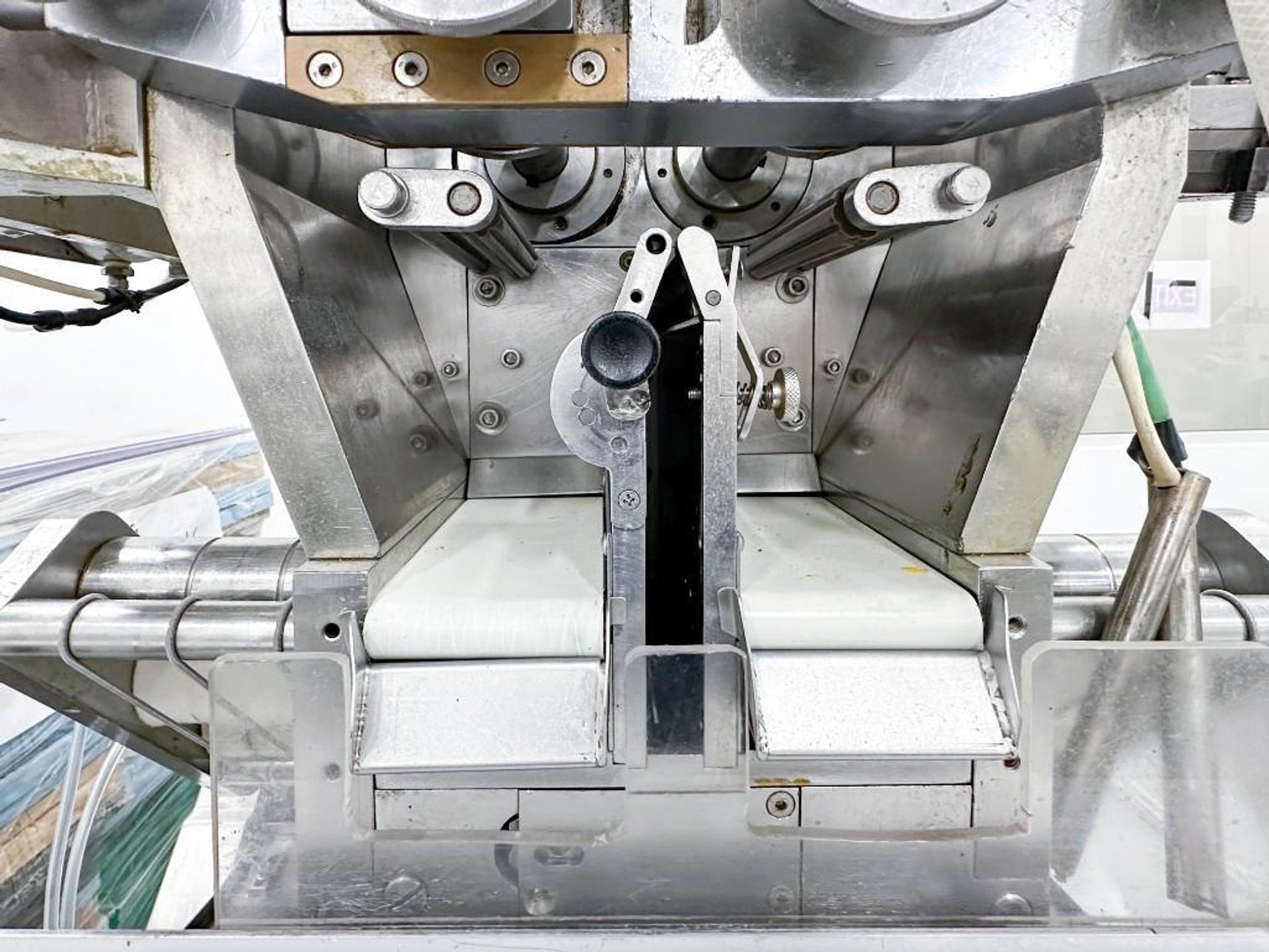

Type: Softgel encapsulator, pilot-scale (smaller system for R&D or small-batch production). Function: Produces soft gelatin capsules by simultaneously forming two gelatin ribbons, filling them with liquid/semi-liquid material (oils, suspensions, nutraceuticals, etc.), and sealing them. Key Features in the Photo: Hopper (top): holds the fill material (oils, vitamins, botanicals, etc.). Pumps/tubing: deliver the fill material with precise dosing into the softgel cavities. Die rollers (middle section): where two gelatin ribbons come together, filled, and sealed into capsules. Cooling/solvent collection tray (bottom area): helps with the ribbon process. Small footprint: confirms it’s likely a pilot or lab-scale system (for R&D or small production runs), not a full industrial line. Applications: Nutraceuticals: fish oil, CBD oil, herbal extracts. Pharmaceuticals: liquid meds, fat-soluble actives. Specialty small-batch products or formulation testing before scaling up. These pilot softgel machines typically produce anywhere from a few thousand capsules per hour

Skidding and Load out charges: There will be loading and skidding charges added to your purchase at market rates for your convenience.

Location: Texas Skidding: $$ Load Out: $$